Unlocking Efficiency: How the Best Screw Air Compressors Drive Productivity in Manufacturing

In the fast-paced world of manufacturing, efficiency is not just a goal; it is a necessity. Among the myriad of tools and technologies that enhance productivity, the Screw Air Compressor stands out as a critical component driving operational excellence. With its ability to deliver consistent and high-quality compressed air, this technology transforms the way manufacturers approach their processes, from assembly lines to pneumatic tools. The unique design of Screw Air Compressors ensures minimal energy wastage and maximizes output, which is essential for companies aiming to improve their bottom line. As we delve deeper into this topic, we will explore how integrating the best Screw Air Compressors into manufacturing workflows not only boosts productivity but also supports sustainable practices, ultimately unlocking unprecedented levels of efficiency in the industry.

The Role of Screw Air Compressors in Modern Manufacturing Efficiency

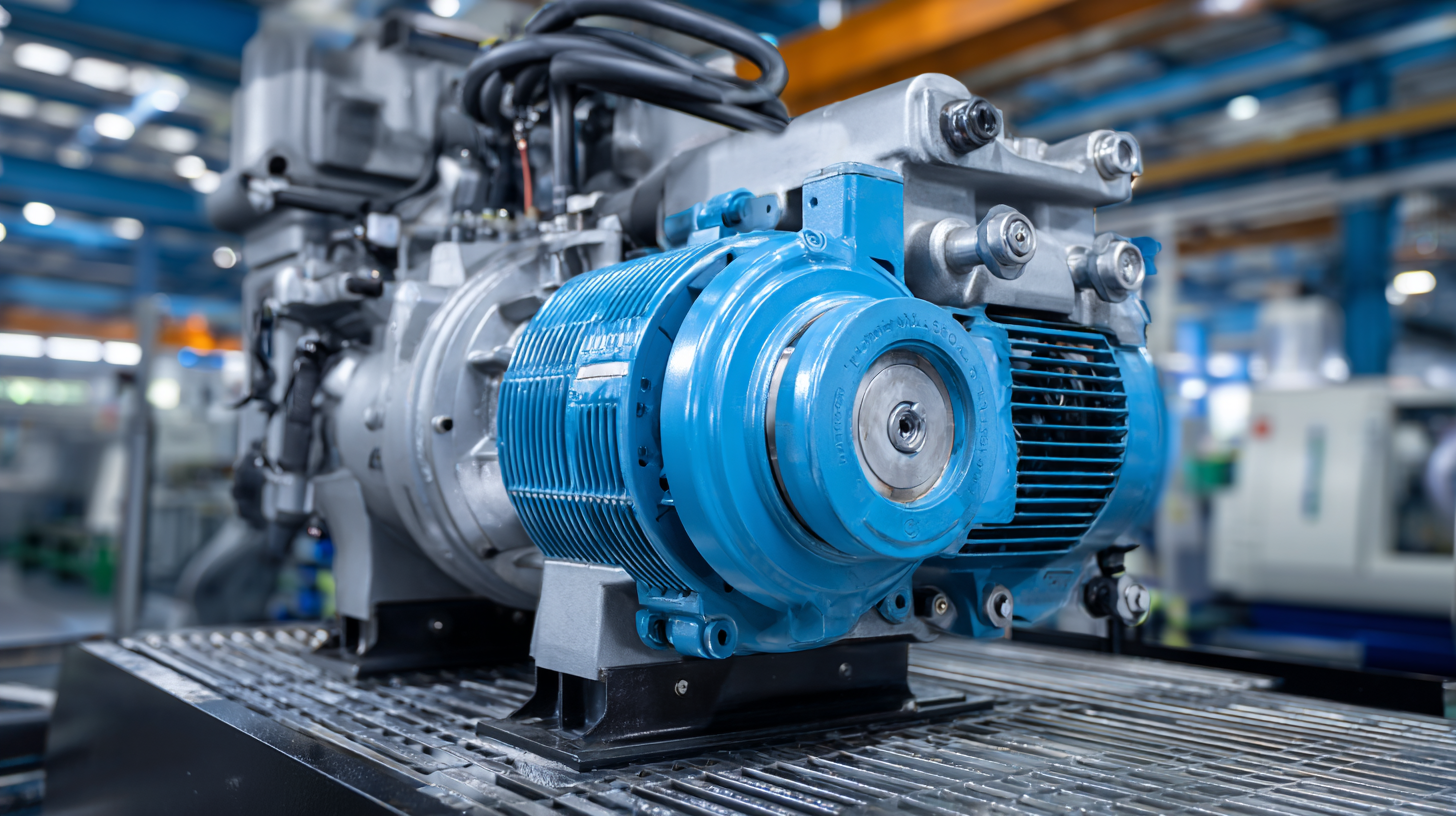

Screw air compressors have become integral to modern manufacturing, significantly boosting operational efficiency. These compressors utilize a rotary screw mechanism, enabling a continuous flow of compressed air that enhances productivity on the factory floor. Their ability to operate smoothly and consistently means less downtime and higher output, which is crucial for manufacturers seeking to maintain competitiveness in a fast-paced market.

Tip: Regular maintenance of your screw air compressors can prevent unexpected breakdowns. Schedule routine checks on filters, oil levels, and belts to ensure optimal performance and longevity of your equipment.

Moreover, screw air compressors offer energy efficiency advantages over traditional air compressors. Their superior design minimizes energy consumption, leading to cost savings and a lower environmental impact. Manufacturers can allocate these savings toward other critical areas, further enhancing overall productivity.

Tip: Consider investing in variable speed drive (VSD) technology. This allows your compressor to adjust its operation based on air demand, optimizing energy use and reducing operational costs effectively.

Key Features of High-Quality Screw Air Compressors for Industrial Use

Screw air compressors have revolutionized the manufacturing landscape, delivering unparalleled efficiency and reliability required in industrial applications. According to a report by the Compressed Air and Gas Institute, screw compressors can achieve efficiencies upwards of 90%, making them significantly more efficient than conventional piston compressors. This remarkable efficiency is primarily attributed to their design, which allows for continuous air flow and reduced energy consumption—critical factors in industries striving for profitability and sustainability.

Screw air compressors have revolutionized the manufacturing landscape, delivering unparalleled efficiency and reliability required in industrial applications. According to a report by the Compressed Air and Gas Institute, screw compressors can achieve efficiencies upwards of 90%, making them significantly more efficient than conventional piston compressors. This remarkable efficiency is primarily attributed to their design, which allows for continuous air flow and reduced energy consumption—critical factors in industries striving for profitability and sustainability.

Key features of high-quality screw air compressors include variable frequency drives (VFD), which enable precise control of motor speed, adjusting output based on real-time air demand. This technology not only optimizes energy usage but also prolongs equipment lifespan, as observed in a study by MarketsandMarkets, indicating that VFD-equipped compressors can reduce energy costs by up to 30%. Additionally, advanced cooling systems within these compressors further enhance performance by preventing overheating and ensuring consistent operation, ultimately driving productivity in manufacturing settings where time and efficiency are paramount.

Impact of Compressor Performance on Production Line Productivity

In the competitive landscape of manufacturing, the performance of screw air compressors plays a pivotal role in enhancing production line productivity. Studies indicate that efficient compressors can improve energy efficiency by up to 20%, which significantly lowers operational costs. According to a report by the Compressed Air and Gas Institute, an optimally running compressor can increase overall production capacity by 15-30%, allowing manufacturers to meet higher demand without additional resource investment.

Tips for maximizing compressor efficiency include regular maintenance to ensure peak performance and reducing air leaks in the system. Even a small leak can waste up to 30% of compressed air energy, making it crucial to conduct routine checks. Additionally, investing in variable speed drive (VSD) technology can lead to further energy savings, as it adjusts the compressor's output based on current air demand, optimizing both performance and cost.

Incorporating advanced monitoring systems can also help manufacturers track compressor performance in real-time, leading to better maintenance scheduling and reduced downtime. A report by the International Energy Agency highlights that industries upgrading to smart monitoring systems have seen productivity gains of 10% or more. Emphasizing the importance of compressor performance is essential for driving both efficiency and productivity in the manufacturing sector.

Unlocking Efficiency: How the Best Screw Air Compressors Drive Productivity in Manufacturing

| Compressor Model | Max Pressure (psi) | Free Air Delivery (CFM) | Power Consumption (kW) | Efficiency Rating (%) |

|---|---|---|---|---|

| Model A | 150 | 40 | 22 | 92 |

| Model B | 120 | 35 | 18 | 90 |

| Model C | 100 | 30 | 15 | 88 |

| Model D | 160 | 42 | 25 | 95 |

| Model E | 140 | 38 | 20 | 91 |

Cost-Benefit Analysis: Investing in Superior Air Compression Technology

Investing in superior air compression technology, specifically screw air compressors, can lead to substantial cost savings and increased productivity for manufacturing operations. These compressors are designed to provide a continuous supply of compressed air, which is essential for powering tools, machinery, and various manufacturing processes. The initial investment in high-quality screw air compressors may be higher than traditional models, but the long-term benefits far outweigh this upfront cost. Maintenance requirements are significantly lower, resulting in reduced downtime and labor costs over the compressor's lifespan.

Moreover, screw air compressors operate more efficiently, producing more compressed air with lower energy consumption. This efficiency translates to lower utility bills, which can constitute a large portion of a manufacturing facility's operational expenses. Additionally, enhanced reliability leads to fewer interruptions in production, allowing manufacturers to meet tight deadlines and maintain high output levels. By conducting a thorough cost-benefit analysis, decision-makers can clearly see how investing in high-performance air compression technology is not just an operational necessity, but a strategic move that positions their business for future success.

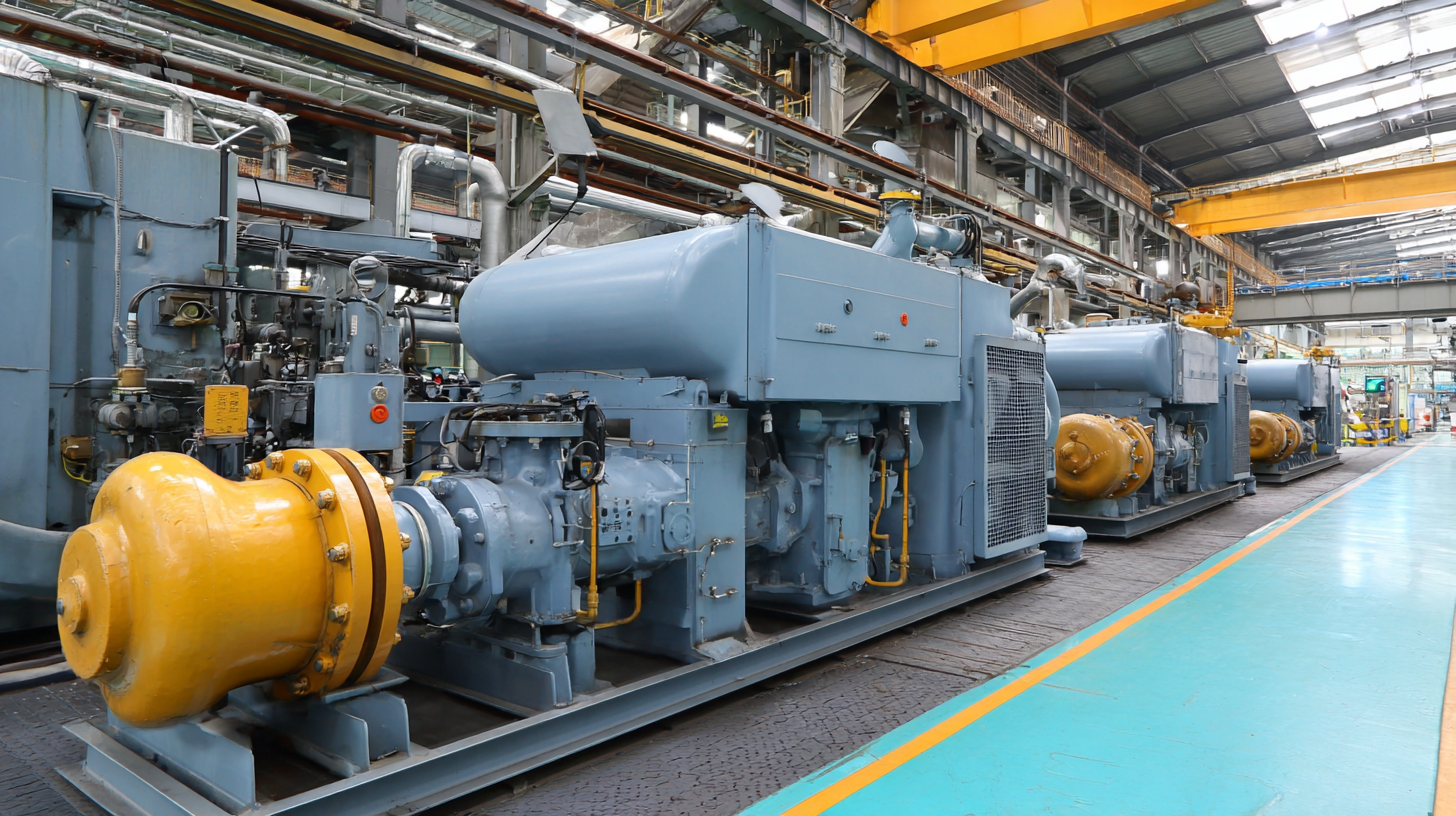

Case Studies: Successful Implementation of Screw Compressors in Chinese Factories

In recent years, Chinese manufacturers have increasingly turned to screw air compressors as a solution for enhancing productivity. One notable example is a large automotive parts manufacturer that replaced its outdated piston compressors with energy-efficient screw compressors. According to a report by the China National Institute of Standardization, implementing screw compressors in industrial settings has shown to increase energy efficiency by up to 30%. This remarkable improvement not only reduces operational costs but also minimizes the carbon footprint of manufacturing processes, aligning with national sustainability goals.

Another case study involves a textile factory that faced chronic air supply shortages, impacting production timelines. After upgrading to a state-of-the-art screw compressor system, the factory reported a 25% increase in output capacity. This transition enabled them to meet rising demand without compromising quality. Industry analysts indicate that compressor technology improvements, such as variable speed drives and advanced control systems, are critical to optimizing performance in high-demand environments. As more factories adopt these cutting-edge solutions, the productivity benefits become increasingly evident across China's manufacturing landscape.

Efficiency Impact of Screw Air Compressors in Manufacturing

The implementation of screw air compressors in Chinese factories has led to a significant increase in productivity, as displayed in the chart. The data shows an increase in productivity from 50% before implementation to 80% after implementation, highlighting the efficiency gains achieved through modern air compression technologies.