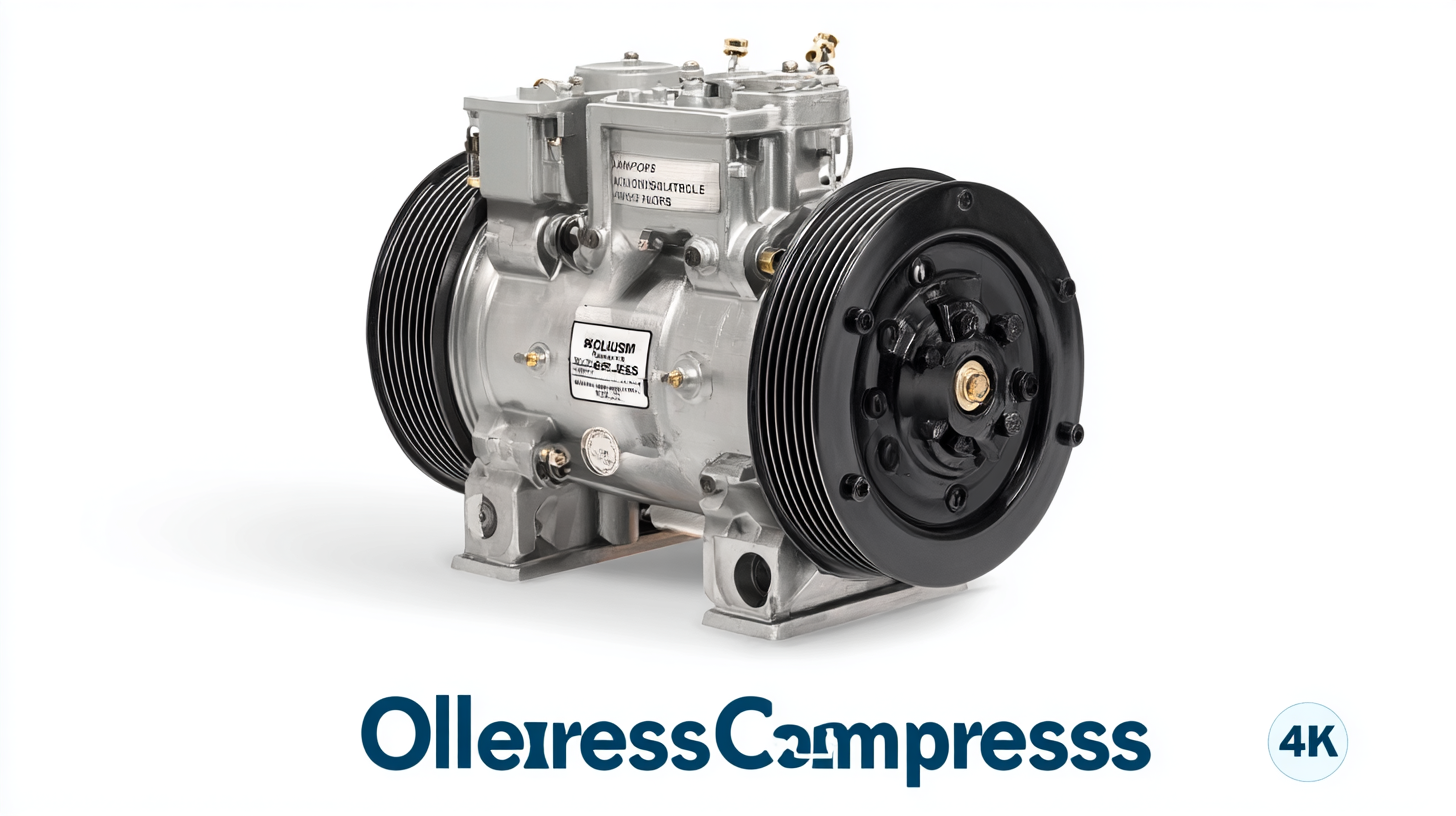

Real World Applications of Best Oilless Air Compressors Addressing Common Challenges

In today's fast-paced industrial landscape, the demand for high-efficiency, low-maintenance equipment is ever-growing, particularly in sectors where air quality is crucial. Oilless air compressors have emerged as a vital solution, offering distinct advantages over traditional models by eliminating the need for lubrication oil, thereby reducing contamination and improving air purity. According to a report by MarketsandMarkets, the global air compressor market is projected to reach $40.69 billion by 2026, driven by the increasing reliance on oilless technologies across various applications, including food and beverage, pharmaceuticals, and electronics manufacturing. With their capacity to address common challenges such as noise pollution, energy inefficiency, and environmental concerns, oilless air compressors are revolutionizing operational processes and setting new standards for sustainability and performance within these industries.

Choosing the Right Oilless Air Compressor for Your Needs

When selecting the right oilless air compressor for your needs, it's crucial to consider both the application and the required specifications. According to a report by the American Society of Mechanical Engineers, oilless air compressors are often preferred in industries requiring clean air, such as food and beverage, pharmaceuticals, and electronics manufacturing. These applications demand compressors that minimize contamination; thus, oilless models, which eliminate the risk of oil discharge into the compressed air, become a viable solution.

Moreover, the energy efficiency of oilless compressors has improved significantly in recent years. The Department of Energy reported a 20% increase in energy efficiency for modern oilless air compressors compared to older models. This is an appealing factor for businesses looking to reduce operational costs while maintaining high productivity levels. Features such as variable speed drives can further enhance energy savings by adjusting the power output based on real-time demand, ensuring that you maximize efficiency and minimize waste. Effective selection involves evaluating your specific operational needs against these advancements, ensuring you choose a model that best fits your requirements.

Top Manufacturers of Oilless Air Compressors: Key Features to Consider

When selecting the best oilless air compressors, it's essential to consider the key features that distinguish top manufacturers in the market. One of the critical factors to assess is the compressor's efficiency and power output. Some manufacturers utilize advanced motor technology that not only boosts performance but also reduces energy consumption, making their products environmentally friendly and cost-effective in the long run.

Durability and maintenance requirements are also significant aspects. Leading brands often design compressors with high-quality materials that enhance longevity and minimize wear and tear. Additionally, many models come with user-friendly features like easy access to components for quick maintenance, which can drastically reduce downtime. Noise level is another factor; the best oilless air compressors are engineered to operate quietly, catering to businesses operating in noise-sensitive environments.

Lastly, consider the range of applications supported by these compressors. Manufacturers that provide versatile models are particularly valuable, as they can cater to diverse needs, from light-duty tasks to heavy industrial use. Understanding these key features will enable consumers to make informed choices and address common challenges faced in various applications effectively.

Common Challenges in Air Compressor Application and Their Solutions

When using air compressors in various settings, several challenges often arise that can hinder performance and efficiency. One common issue is noise pollution, which can be particularly disruptive in work environments such as hospitals or offices. Oilless air compressors have emerged as a preferred solution because they operate more quietly than traditional compressors. By eliminating oil in the compression process, these systems not only reduce noise levels but also minimize maintenance needs, allowing for a smoother and more efficient operation.

Another prevalent challenge is the risk of contamination. In industries like food and beverage production or pharmaceuticals, maintaining clean air is crucial. Oilless air compressors address this by providing clean, oil-free air that eliminates the risk of oil contamination, ensuring compliance with industry standards. This reliability makes them ideal for sensitive applications where air purity is non-negotiable. By leveraging the capabilities of oilless air compressors, businesses can effectively tackle these common challenges, leading to improved productivity and quality in their operations.

Real-World Success Stories: Oilless Air Compressors in Action

In various industries, oilless air compressors have emerged as crucial tools, addressing multiple operational challenges. For instance, in the food and beverage sector, the need for clean, contamination-free compressed air is paramount. According to a report by the Compressed Air and Gas Institute, oilless compressors ensure adherence to stringent safety standards without the risk of oil contamination, making them ideal for packaging and processing applications. Companies like Nestlé have successfully implemented these systems, enhancing product safety and operational efficiency.

In the medical field, the reliability of oilless air compressors cannot be overstated. Hospitals and medical facilities require dependable equipment to maintain life-saving devices. A survey from Healthcare Compressed Air Services reveals that over 68% of medical professionals prefer oilless systems for their low maintenance and high purity air output. Successful implementations in hospitals have demonstrated significant reductions in service downtime, allowing for uninterrupted patient care.

Tips: When selecting an oilless air compressor, consider energy efficiency ratings to lower operational costs. Additionally, regular maintenance checks can significantly increase the lifespan of your equipment. Finally, ensure compatibility with your specific application to maximize performance and reliability.

Digital Innovations Transforming Oilless Air Compressor Technology

Digital innovations are revolutionizing the landscape of oilless air compressor technology, addressing long-standing challenges faced by users across various industries. With advancements in sensor technology and IoT integration, modern oilless air compressors now offer real-time monitoring of performance metrics. This capability allows for predictive maintenance, ensuring that compressors operate at peak efficiency and minimizing downtime. Users can now track usage patterns and receive notifications for potential issues before they lead to costly breakdowns.

Digital innovations are revolutionizing the landscape of oilless air compressor technology, addressing long-standing challenges faced by users across various industries. With advancements in sensor technology and IoT integration, modern oilless air compressors now offer real-time monitoring of performance metrics. This capability allows for predictive maintenance, ensuring that compressors operate at peak efficiency and minimizing downtime. Users can now track usage patterns and receive notifications for potential issues before they lead to costly breakdowns.

Moreover, the introduction of intelligent control systems enhances the user experience by optimizing energy consumption. These smart compressors are equipped with adaptive algorithms that analyze load demands, allowing the unit to adjust its output efficiently. As a result, businesses can significantly reduce energy costs while still meeting their operational needs.

This shift not only promotes sustainability but also showcases how digital innovations can drive enhanced productivity in industries reliant on compressed air systems. The fusion of traditional machinery with cutting-edge technology exemplifies how the future of oilless air compressors is promising, tackling previous limitations and paving the way for more reliable and efficient solutions.