Understanding the Common Challenges with Oilless Air Compressors for Global Buyers

In the rapidly evolving landscape of industrial machinery, the Oilless Air Compressor stands out as a critical component for a variety of applications. As global buyers increasingly seek sustainable and efficient solutions, understanding the common challenges associated with oilless air compressors becomes paramount. These compressors promise cleaner operation and reduced maintenance needs, yet they present unique hurdles that can affect performance and longevity. From noise levels to initial investment costs and technology limitations, discerning buyers must navigate these complexities to make informed purchasing decisions. This blog aims to delve into the intricacies of oilless air compressors, providing insights that empower buyers to effectively tackle these challenges, ensuring they reap the full benefits of their investment.

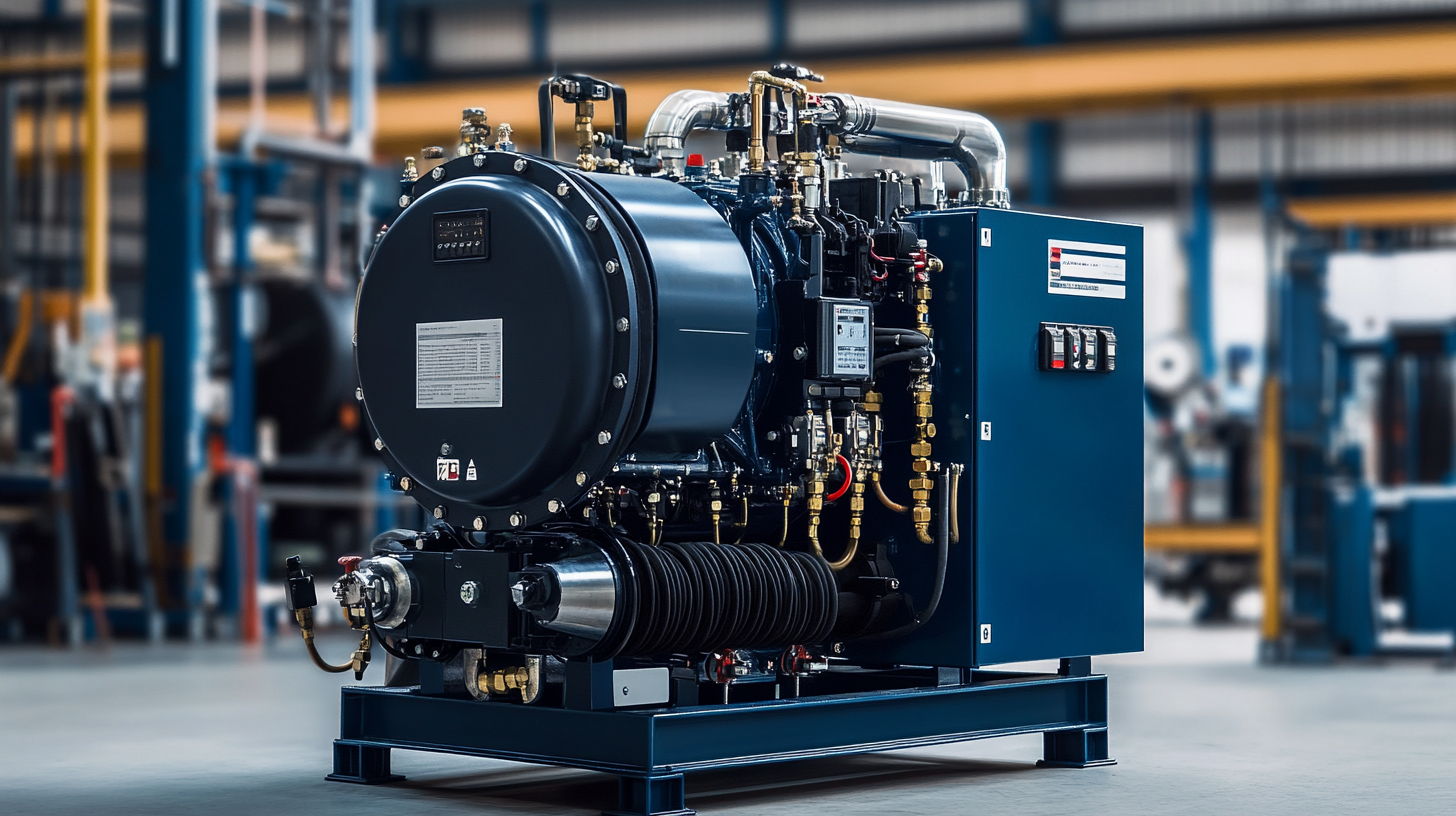

Overview of Oilless Air Compressors and Their Unique Features

Oilless air compressors have gained significant traction in various industries due to their unique features and advantages. Unlike traditional oil-lubricated compressors, oilless models utilize advanced engineering materials that allow for frictionless operation, resulting in cleaner air output and lower maintenance requirements. According to the International Compressor Manufacturers Association (ICMA), oilless compressors accounted for approximately 30% of the global air compressor market share in 2021, reflecting a growing preference for maintenance-free solutions in sectors such as food processing, pharmaceuticals, and electronics manufacturing.

One of the standout features of oilless air compressors is their ability to operate efficiently in environments where oil contamination would pose serious risks. This attribute is particularly crucial in industries that require high levels of purity, such as medical applications, where even the slightest contamination can lead to significant safety concerns. Additionally, the relatively silent operation of oilless compressors makes them an ideal choice for urban applications and confined spaces, enabling compliance with environmental noise regulations. Research from market analysis firm Freedonia Group indicates that the demand for oilless air compressors is expected to grow at an annual rate of 5.2% through 2026, driven by these unique benefits and the advancement of energy-efficient technologies.

Common Issues Faced by Global Buyers of Oilless Air Compressors

Oilless air compressors are gaining significant momentum in the global market, driven by increasing demand for energy-efficient and environmentally friendly solutions. However, global buyers often encounter common challenges that can hinder their purchasing decisions. One major issue is the variability in quality and performance across different brands and models. Buyers must navigate through a plethora of options, ensuring that the compressors not only meet their operational requirements but also adhere to sustainability standards.

Oilless air compressors are gaining significant momentum in the global market, driven by increasing demand for energy-efficient and environmentally friendly solutions. However, global buyers often encounter common challenges that can hinder their purchasing decisions. One major issue is the variability in quality and performance across different brands and models. Buyers must navigate through a plethora of options, ensuring that the compressors not only meet their operational requirements but also adhere to sustainability standards.

Another challenge lies in the maintenance and reliability of oilless air compressors. While they offer the advantage of reduced oil usage, some models may have durability concerns or require specific maintenance practices that buyers may not be aware of. As the air compressor market anticipates robust growth, projected to reach $68.86 billion by 2030, buyers need to stay informed about the innovations and advancements in the industry. By understanding these common issues – from performance inconsistency to maintenance requirements – global buyers can make more informed decisions, ensuring that their investments yield long-term benefits in their respective industries.

Maintenance Challenges and Best Practices for Oilless Air Compressors

Oilless air compressors offer a range of advantages, particularly in environments where oil contamination is a concern. However, they are not without their maintenance challenges. One of the most common issues faced by users is the build-up of dust and debris in the compressor’s air intake and filters. This accumulation can lead to decreased efficiency and increased energy consumption. Regularly inspecting and cleaning the filters is essential to ensure optimal performance and longevity of the unit.

Another challenge is the wear and tear of components over time. Unlike their oil-lubricated counterparts, oilless compressors rely heavily on precise engineering and quality materials to function efficiently. Preventive maintenance practices, such as monitoring operating temperatures and replacing worn components promptly, can help mitigate these issues. Users should also pay attention to the manufacturer’s recommendations for maintenance schedules to avoid unexpected downtime and costly repairs. By adopting best practices for care and upkeep, global buyers can significantly enhance the reliability and lifespan of their oilless air compressors.

Comparing Oilless and Oil-Lubricated Air Compressors: Pros and Cons

When it comes to choosing between oilless and oil-lubricated air compressors, understanding their pros and cons is crucial for making an informed decision. Oilless air compressors are favored for their low maintenance requirements and cleaner operation, making them ideal for applications where oil contamination cannot be tolerated, such as in food processing or pharmaceuticals. They also tend to be more portable due to their lighter weight, making them suitable for various on-the-go tasks.

On the other hand, oil-lubricated air compressors are known for their durability and quieter operation. They typically offer higher efficiency, especially during prolonged usage, which can make them a better choice for heavy-duty industrial applications. However, they require regular oil changes and maintenance, which can increase operational costs over time.

Tips for buyers include evaluating the specific application needs and the environment where the compressor will be used. If cleanliness is a priority, an oilless model may be best, while those needing robust performance in challenging conditions might lean towards oil-lubricated options. Additionally, consider energy efficiency ratings, as this will significantly impact long-term operational costs.

Key Considerations for Selecting the Right Oilless Air Compressor

When selecting the right oilless air compressor, global buyers must navigate an array of challenges. Among the foremost considerations are the performance specifications that align with specific applications. According to a recent industry report, the demand for oilless air compressors is expected to reach over $1.3 billion by 2025, highlighting the shift towards more environmentally friendly and maintenance-free solutions. Buyers should focus on parameters like maximum pressure, flow rate, and duty cycle based on their operational needs.

Another significant aspect is the noise level produced by oilless compressors, as many users seek quieter alternatives for home and professional environments. Research indicates that noise levels above 85 decibels can lead to long-term hearing damage, making it essential to choose a compressor with sound-dampening features. Furthermore, maintenance requirements should also be evaluated; oilless models are often marketed as low-maintenance, but it is crucial to understand the need for periodic checks to ensure optimal performance. Balancing these factors will enable buyers to make informed decisions that align with their operational goals while promoting sustainable practices in their industries.

Understanding the Common Challenges with Oilless Air Compressors for Global Buyers - Key Considerations for Selecting the Right Oilless Air Compressor

| Dimension | Consideration | Challenges | Recommended Solutions |

|---|---|---|---|

| Noise Level | Choosing low-noise models for quiet environments | Excessive noise during operation | Look for compressors with sound insulation features |

| Heat Generation | Evaluating models with efficient cooling mechanisms | Overheating during prolonged use | Select compressors with built-in thermal protection |

| Power Consumption | Assessing energy efficiency ratings | High operational costs | Look for energy-efficient models |

| Durability | Choosing compressors made from high-quality materials | Frequent breakdowns | Prioritize reputable manufacturers |

| Maintenance | Evaluating ease of maintenance and availability of parts | Complex maintenance processes | Choose models with clear maintenance guidelines |