5 Essential Tips for Choosing the Best Oil-free Air Compressor

As industries increasingly prioritize sustainability and operational efficiency, the demand for Oil-free Air Compressors has surged, driven by advancements in technology and a growing awareness of environmental impacts. According to a recent report by MarketsandMarkets, the air compressor market is projected to reach USD 40.1 billion by 2025, with oil-free compressors expected to account for a significant share due to their reduced maintenance costs and environmental benefits. With applications ranging from manufacturing to healthcare, these compressors offer a cleaner alternative that eliminates the risk of oil contamination in sensitive environments. Understanding the critical factors in selecting an Oil-free Air Compressor is essential for businesses aiming to enhance their operational workflow while adhering to stringent regulatory standards. This blog will delve into five essential tips that will guide you towards making an informed choice in 2025 and beyond.

As industries increasingly prioritize sustainability and operational efficiency, the demand for Oil-free Air Compressors has surged, driven by advancements in technology and a growing awareness of environmental impacts. According to a recent report by MarketsandMarkets, the air compressor market is projected to reach USD 40.1 billion by 2025, with oil-free compressors expected to account for a significant share due to their reduced maintenance costs and environmental benefits. With applications ranging from manufacturing to healthcare, these compressors offer a cleaner alternative that eliminates the risk of oil contamination in sensitive environments. Understanding the critical factors in selecting an Oil-free Air Compressor is essential for businesses aiming to enhance their operational workflow while adhering to stringent regulatory standards. This blog will delve into five essential tips that will guide you towards making an informed choice in 2025 and beyond.

Understanding the Benefits of Oil-free Air Compressors in Various Industries

Oil-free air compressors have gained significant traction across various industries due to their inherent advantages. One of the most compelling benefits is their ability to provide clean, contaminant-free air, making them ideal for applications where air quality is paramount. In food processing and medical industries, for instance, the absence of oil particles is crucial, as even minute contamination can lead to product spoilage or health hazards. This level of cleanliness ensures compliance with stringent regulations and enhances overall operational efficiency.

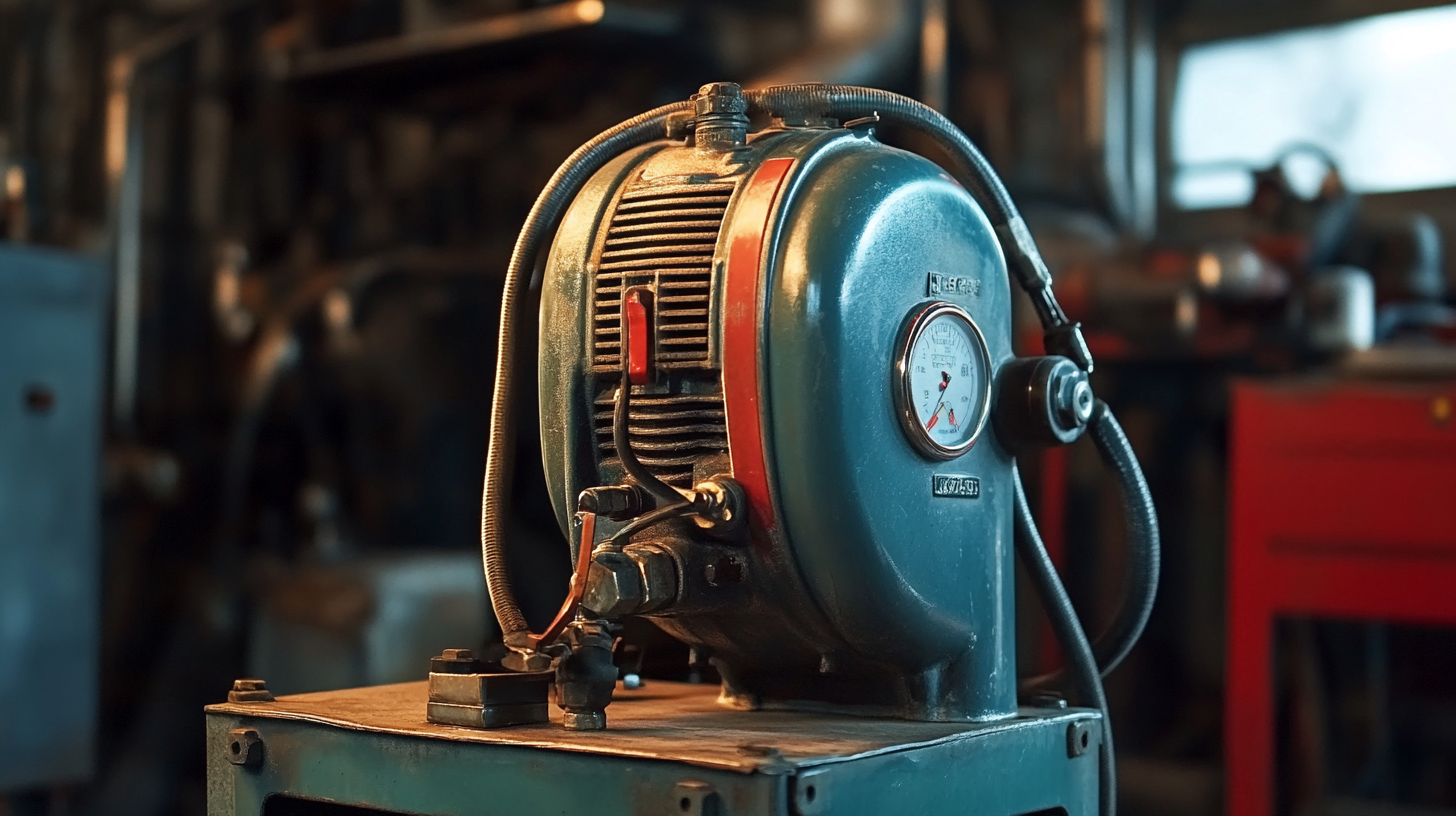

Furthermore, oil-free compressors are known for their lower maintenance requirements and operational costs. Without the need for oil changes or filtration systems, businesses can significantly reduce downtime and service expenses. This makes them a convenient choice for manufacturers and workshops that rely heavily on consistent air supply. Additionally, the compact design of many oil-free models allows for easier installation in tight spaces, making them suitable for a range of work environments. As industries continue to prioritize sustainability and efficiency, the demand for oil-free air compressors is expected to grow, reflecting a shift towards more eco-friendly and cost-effective solutions.

Key Factors to Consider: Size and Capacity of Oil-free Air Compressors

When selecting an oil-free air compressor, one of the most crucial factors to consider is its size and capacity. An appropriate size ensures that the compressor fits your workspace and does not occupy unnecessary space. Moreover, choosing the correct capacity is vital for meeting the demands of your applications, whether for home use or industrial purposes. Smaller models may suffice for light tasks like inflating tires or powering airbrushes, while heavier tasks may require compressors with higher capacity to ensure consistent performance.

In the context of the growing demand for compressors, the global market is projected to reach USD 21.34 billion by 2033, driven by a CAGR of 5.7%. This suggests an increasing trend in the adoption of air compressors across various industries, highlighting the importance of selecting the right equipment. Proper size and adequate capacity do not just enhance efficiency but also contribute significantly to the longevity and reliability of your compressor. Understanding these key factors will help ensure that you invest in a model that not only meets your immediate needs but also adapts to future demands.

Comparative Analysis: Noise Levels of Oil-free vs. Oil-lubricated Compressors

When selecting an air compressor, one crucial aspect to consider is the noise level associated with different types of compressors—specifically, oil-free versus oil-lubricated models.

Oil-free air compressors are often favored for their quieter operation. This is primarily due to the lack of oil in the compression chamber, which leads to fewer moving parts and reduced friction.

As a result, many users find that oil-free compressors operate at lower decibel levels, making them ideal for indoor use or environments where noise pollution is a concern.

Oil-free air compressors are often favored for their quieter operation. This is primarily due to the lack of oil in the compression chamber, which leads to fewer moving parts and reduced friction.

As a result, many users find that oil-free compressors operate at lower decibel levels, making them ideal for indoor use or environments where noise pollution is a concern.

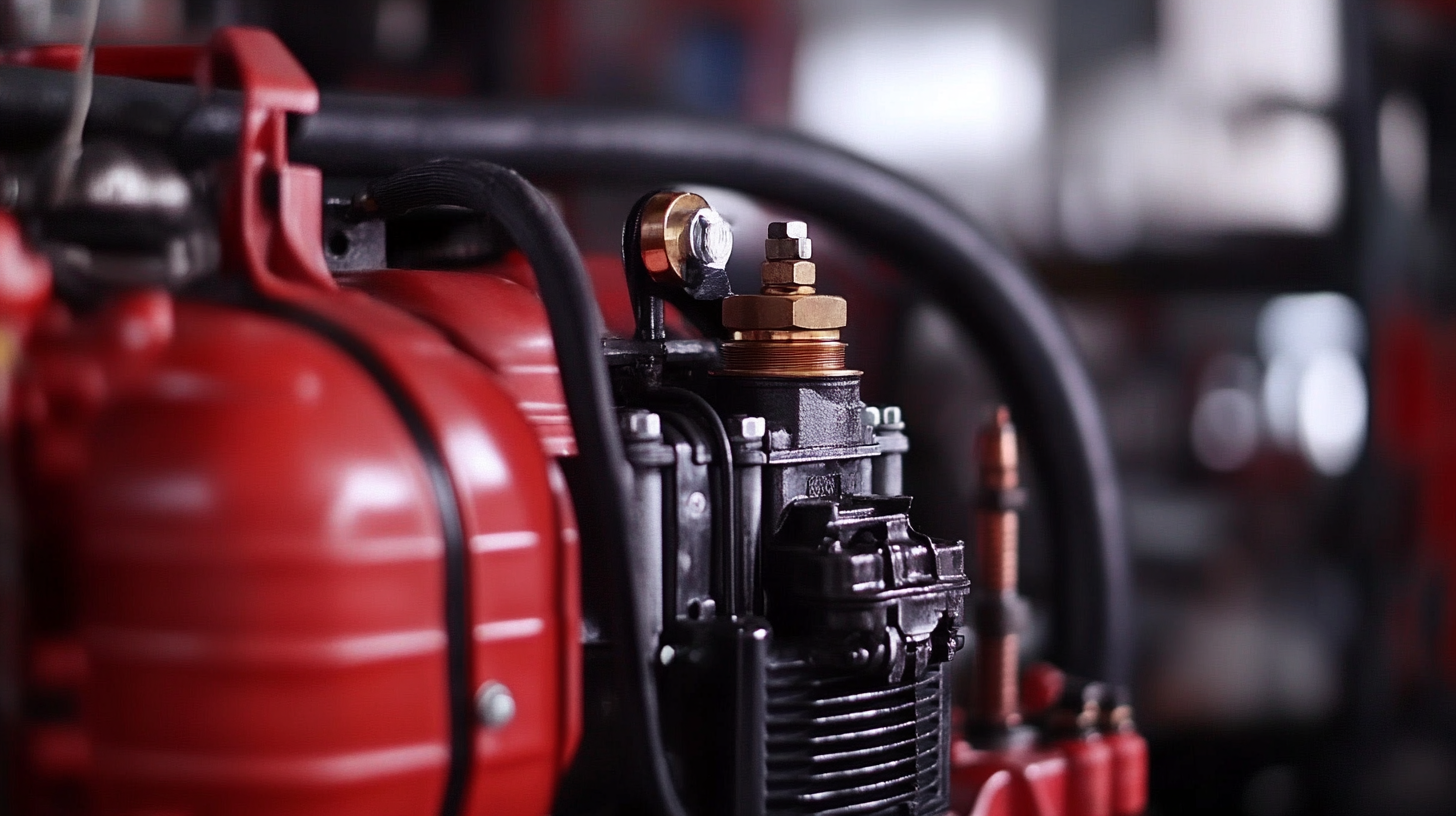

On the other hand, oil-lubricated compressors, while generally more powerful and capable of handling heavier tasks, tend to produce higher noise levels. The oil in these compressors can generate excess heat and friction, leading to louder operation. However, advancements in technology have led to some oil-lubricated units that incorporate sound-dampening features, aiming to reduce their overall noise output.

Ultimately, understanding the noise levels associated with each type can help you select a compressor that aligns with your specific needs and environment, ensuring a balance between performance and comfort.

Maintenance Requirements: How Oil-free Compressors Reduce Long-term Costs

When considering an oil-free air compressor, maintenance requirements play a crucial role in long-term cost efficiency. Oil-free compressors significantly reduce maintenance needs compared to their oil-filled counterparts, leading to lower operational expenses over time. According to industry reports, the global air compressor market is witnessing a shift towards oil-free technology, driven by its sustainability benefits and lower maintenance costs. The oil-free dental air compressor market, for example, is projected to see substantial growth, reflecting a broader trend of industries prioritizing efficiency and reduced upkeep.

In New England alone, the air compressor market is expected to reach USD 225 million by 2024, with a growth rate of 3.5% from 2025 to 2030. This growth is indicative of a growing preference for oil-free compressors, which not only minimize operational interruptions due to oil changes but also enhance cleanliness and reduce the risk of contamination. Utilizing an oil-free compressor can therefore be a smart investment for long-term savings and operational efficiency, particularly for sectors requiring stringent hygiene standards, such as dental and healthcare applications.

Evaluating Performance: PSI Ratings and Their Importance in Your Selection Process

When selecting an oil-free air compressor, understanding PSI (pounds per square inch) ratings is crucial for ensuring optimal performance. PSI is a measure of pressure output, and higher PSI ratings indicate a greater ability to perform demanding tasks. According to industry reports, most air tools typically require a pressure range of 70 to 90 PSI, making it essential to choose a compressor that meets or exceeds these specifications. For instance, a compressor with a maximum PSI of 120 would not only handle basic tasks with ease but also provide the flexibility needed for more demanding applications.

Beyond the basic pressure capabilities, the efficiency of an oil-free air compressor can also hinge on its ability to maintain consistent PSI levels during operation. Data from a recent study by the Air Compressor Institute highlights that models delivering continuous PSI output experience less wear and longer service life, enhancing overall productivity. As you evaluate potential options, consider compressors that not only meet the required PSI for your applications but also maintain that pressure over prolonged use, ensuring robust performance and reliability in your projects.