10 Amazing Tips to Choose the Best Oilless Air Compressor for Your Business Needs

When it comes to selecting the right equipment for your business, understanding the nuances of an Oilless Air Compressor can make a significant difference in your operational efficiency and maintenance costs. These compressors are designed to deliver compressed air without the need for oil, which not only reduces the risk of contamination but also minimizes the upkeep associated with oil changes and leaks. As businesses strive for sustainability and improved productivity, choosing the ideal Oilless Air Compressor becomes essential. In this blog, we will provide you with ten amazing tips that will serve as a comprehensive checklist for making an informed decision tailored to your specific needs. Whether you're in manufacturing, automotive, or any sector that relies on compressed air, these insights will help you navigate the options available and select the best Oilless Air Compressor for your unique business requirements.

Understanding Your Business Requirements for an Oilless Air Compressor

When selecting an oilless air compressor for your business, it's crucial to first understand the specific requirements of your operations. Different industries, such as craft brewing or food and beverage processing, have unique demands that influence the type of compressor needed. For example, in environments where cleanliness is paramount, such as breweries, an oil-free compressor can prevent contamination and ensure product quality. Furthermore, considering airflow requirements—measured in cubic feet per minute (CFM)—is essential to ensure that the compressor can handle the workload effectively without causing downtime.

In addition to airflow, businesses must evaluate the pressure levels their operations require, which can vary widely depending on applications. For instance, some tasks may only need lower pressure, while others, like those in industrial settings, may require higher psi ratings. It’s also beneficial to look at the energy efficiency of potential compressors, as this can lead to significant cost savings over time. By thoroughly analyzing these factors, businesses can make informed decisions that align with their operational needs and financial considerations, thereby optimizing their productivity and efficiency in the long run.

10 Amazing Tips to Choose the Best Oilless Air Compressor for Your Business Needs

| Tip | Description | Application | Power Requirement |

|---|---|---|---|

| Understand Your Needs | Evaluate the specific applications you intend to use the compressor for. | Painting, Pneumatic Tools | 1-5 HP |

| Noise Level | Consider the noise levels, especially if operating in a compact or sensitive area. | Indoor Use, Workshops | AC or DC Options Available |

| Portability | Assess the need for a portable or stationary unit based on your workspace. | Job Sites, Various Locations | 1-2 HP for Portable |

| Tank Size | Choose a tank size suitable for your usage frequency and duration. | Long Running Tools | 5-10 Gallons |

| Maintenance | Consider the maintenance needs and ease of service for the compressor. | Commercial Applications | Varies by Model |

| Energy Efficiency | Look for energy-efficient models to reduce operational costs. | All Applications | 2-10 HP |

| Pressure Ratings | Ensure the compressor meets the pressure requirements for your tools. | High-Pressure Tools | Up to 120 PSI |

| Budget | Define your budget to narrow down your options effectively. | Small Business, Startups | $200 - $2000 |

| Warranty and Support | Check warranty conditions and manufacturer support options. | All Industries | Varies by Brand |

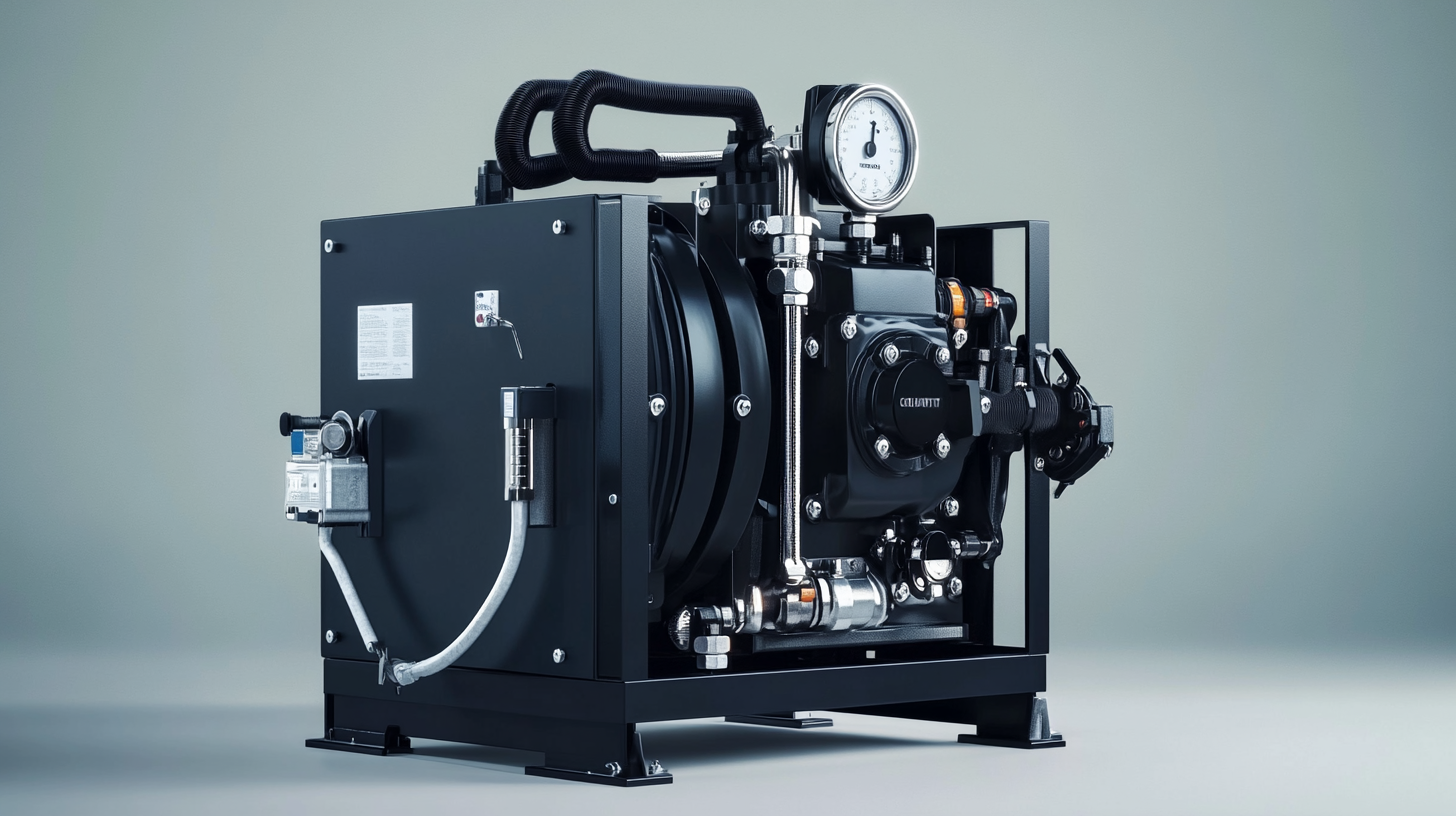

Key Features to Look for in an Oilless Air Compressor

When selecting the best oilless air compressor for your business, understanding key features is crucial to ensure that the equipment meets your operational demands. Firstly, consider the power source of the air compressor. Electric units are typically preferred for their efficiency and low maintenance needs, while portable gas-powered units offer flexibility for outdoor applications. The tank size is another vital factor; a larger tank can provide a more sustained airflow, beneficial for longer tasks, while a smaller tank enhances portability.

A critical feature of oilless air compressors is their noise level, especially if you're operating in a confined space or quiet environment. Look for models designed with noise reduction technology. Additionally, assess the compressor's duty cycle rating, which indicates how long it can run continuously without overheating. A higher duty cycle is ideal for heavy usage, as it ensures your compressor can keep pace with constant demands. Finally, don't overlook the importance of warranty and customer support, as these factors can significantly impact long-term satisfaction and operational efficiency.

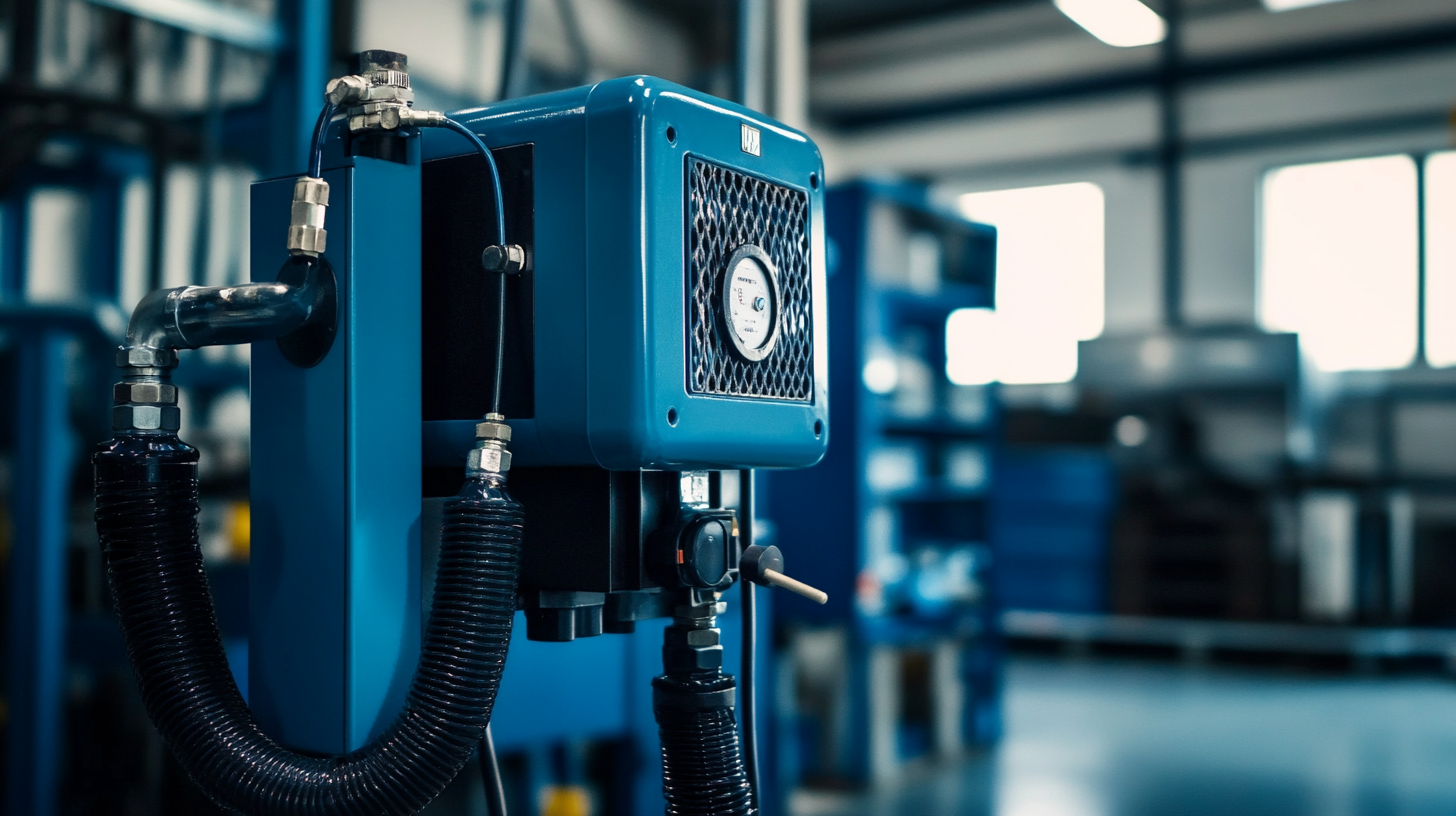

Evaluating the Performance Specifications Needed for Your Industry

When selecting the best oilless air compressor for your business needs, evaluating the performance specifications required for your industry is crucial. Different sectors, such as manufacturing, automotive, and food processing, have varying air demands. For instance, a report by the Compressed Air and Gas Institute (CAGI) indicates that industries like manufacturing typically require compressors that operate under sustained pressure settings of around 90-100 psi. In contrast, food processing facilities often adhere to stricter hygiene standards, necessitating compressors with low oil carryover levels and advanced filtration systems.

To ensure you choose the right compressor, consider the duty cycle. Continuous-duty compressors, often recommended for manufacturing applications, need to operate for prolonged periods without overheating. Businesses looking for versatility in their air supply might benefit from variable speed compressors, which can adjust motor speed to match airflow demand, optimizing energy consumption. Furthermore, always check noise levels; according to a study by the American Society of Mechanical Engineers (ASME), noise can impact worker productivity, with decibel levels over 85 dB being particularly disruptive.

Another important factor is the tank size, which depends on the volume of air required. Larger tanks are suitable for heavy-duty tasks, while smaller tanks might suffice for seasonal or light-duty operations. Choosing the appropriate horsepower is also key; a general rule of thumb suggests that 1 HP can generate around 4 CFM (cubic feet per minute) of air at 90 psi, which can guide you in matching your compressor’s output to your operational needs.

Performance Specifications Comparison of Oilless Air Compressors

This bar chart illustrates the key performance specifications of different oilless air compressors relevant to various business needs. The metrics included are CFM (Cubic Feet per Minute), PSI (Pounds per Square Inch), noise level in decibels, tank capacity in gallons, and weight in pounds. Evaluating these specifications can help businesses choose the right compressor for their applications.

Comparing Brands and Models: What to Know Before You Buy

When choosing an oilless air compressor, it is essential to understand the key differences between brands and models to meet your business needs effectively. According to a report by Research and Markets, the global air compressor market is expected to grow at a CAGR of 4.2% from 2021 to 2026. This increase is driven by the rising demand for energy-efficient and environmentally friendly products, making the selection of an oilless compressor more critical than ever.

When comparing models, consider factors such as noise levels, power consumption, and tank capacity. For instance, a study published in the Journal of Compressed Air Technology found that oil-free compressors significantly reduce noise pollution, operating around 60-70 dB, compared to their oiled counterparts, which often exceed 80 dB. Additionally, evaluating the compressor's duty cycle and recovery time is critical for maintaining operational efficiency. Brands like Makita and California Air Tools are known for their reliable performance and user-friendly features, making them popular choices among businesses looking to optimize their air compression systems.

Budgeting and Cost-Effectiveness: Finding the Right Oilless Air Compressor

When choosing the right oilless air compressor for your business, understanding budgeting and cost-effectiveness is crucial. Oilless compressors may come with a higher initial investment, but they can lead to significant savings in maintenance and operational costs over time. Investing in a high-quality unit, such as those designed for specialized industries like air separation or steel production, will pay off in efficiency and reliability, ultimately benefiting your bottom line.

In evaluating options, consider the energy consumption of the compressor. Some modern models are designed to offer both high flow rates and low energy usage, making them particularly attractive for businesses aiming to reduce operational costs while maintaining productivity. By selecting an energy-efficient oilless air compressor, you not only maximize performance but also contribute to a more sustainable business model, aligning with contemporary environmental standards and expectations.