Dual-Specification Nitrogen Boosters Empower the Production of New Green Building Materials with Full Confidence

2025-05-30

In the field of modern industrial production, gas pressure control plays a vital role in ensuring the stability of production processes and product quality. Recently, an enterprise in the steel structure sector successfully introduced two nitrogen boosters, injecting strong momentum into its production processes, significantly improving production efficiency and quality, and setting a model example for the application of industrial gas equipment.

Founded in January 2021 with a registered capital of 10 million yuan, a Hebei-based enterprise specializes in steel structure foundation engineering, research, development, manufacturing, and construction of new prefabricated steel structure residences. It is committed to building a research, development, production, and export manufacturing base for new green energy-saving building materials, while actively advancing projects for reduction furnace and carbon-ceramic new material research, development, and production bases. As a comprehensive industrial enterprise, it has strict requirements for nitrogen pressure during production.

To meet production needs, the enterprise purchased two nitrogen boosters from MFG with different working pressures:

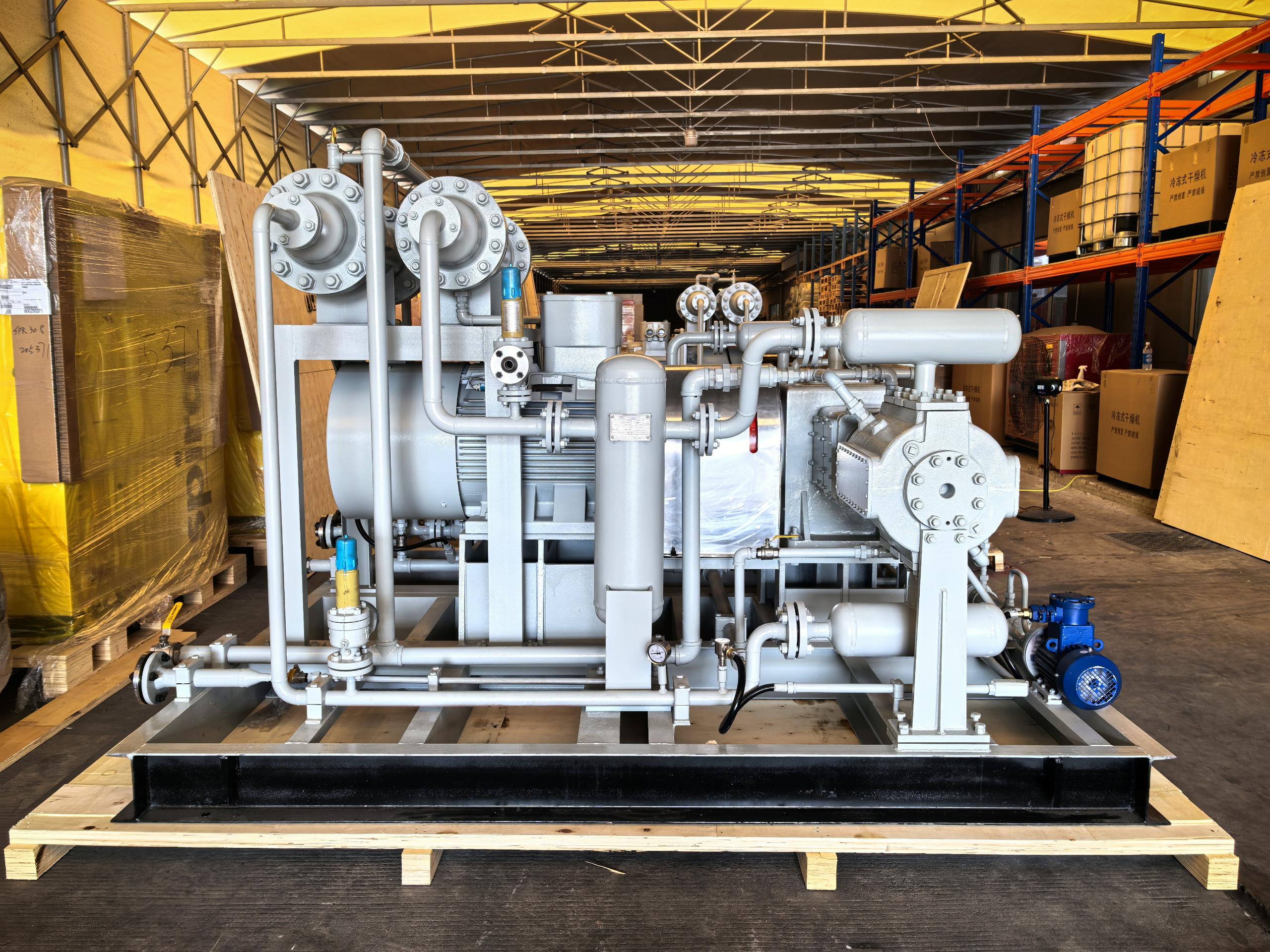

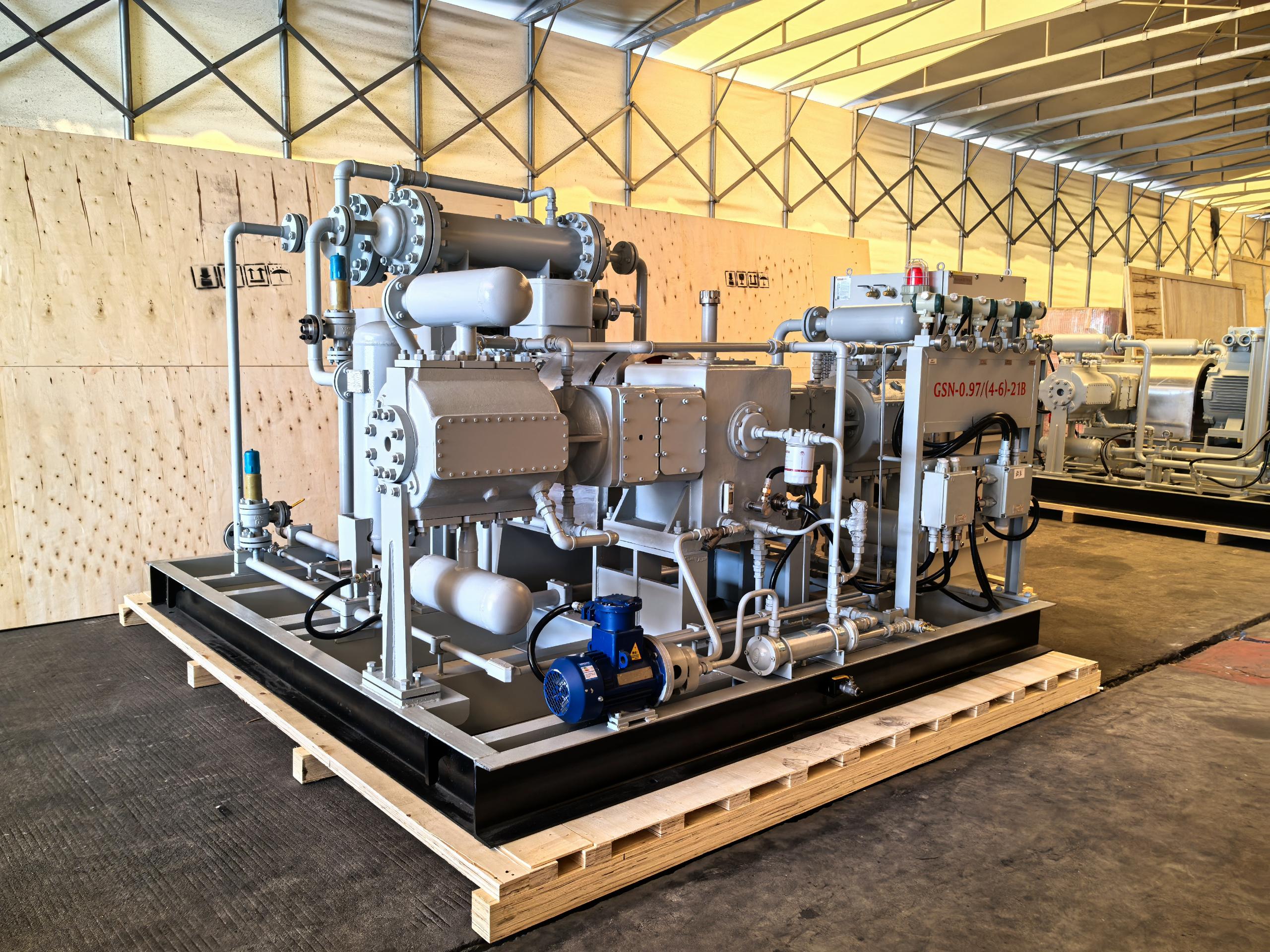

1. One booster, model GSN-0.97/(4-6)-21B, can stably increase nitrogen pressure to 21 bar;

2. The other, model GSN-0.97/(4-6)-50B, can raise nitrogen pressure to 50 bar.

The commissioning of these two nitrogen boosters precisely matches the enterprise's nitrogen pressure requirements across different production processes.

In steel structure manufacturing and new material research and production, stable and appropriate nitrogen pressure is a key factor in ensuring welding quality and material processing effects. For example, in the welding process, using nitrogen with stable pressure provided by the booster for protection can effectively prevent metal oxidation, improve weld quality, and reduce defective rates. In new material processing procedures, nitrogen at specific pressures helps optimize material properties, ensuring products meet higher quality standards.

These two nitrogen boosters not only excel in pressure enhancement but also provide a solid guarantee for production through their reliability and stability. Advanced technology and high-quality manufacturing processes enable the equipment to maintain high efficiency during long-term continuous operation, reducing the impact of equipment failures on production schedules. Meanwhile, the equipment's simple operation and convenient maintenance significantly reduce the enterprise's costs and efforts in equipment management and maintenance.

As a wholly-owned subsidiary of an industrial group, the enterprise leverages the group's comprehensive advantages in research and development, design, manufacturing, sales, and service to select these two nitrogen boosters, empowering its production. The successful application of MFG nitrogen boosters not only reflects the enterprise's emphasis on production process optimization but also demonstrates the important value of industrial nitrogen generator equipment in modern industrial production.

In future industrial development, with the continuous upgrading of production processes and increasing requirements for product quality, industrial gas equipment such as nitrogen boosters will play an even more critical role. More enterprises will achieve dual improvements in production efficiency and quality by introducing advanced process gas treatment equipment, gaining a competitive edge in the fierce market competition.